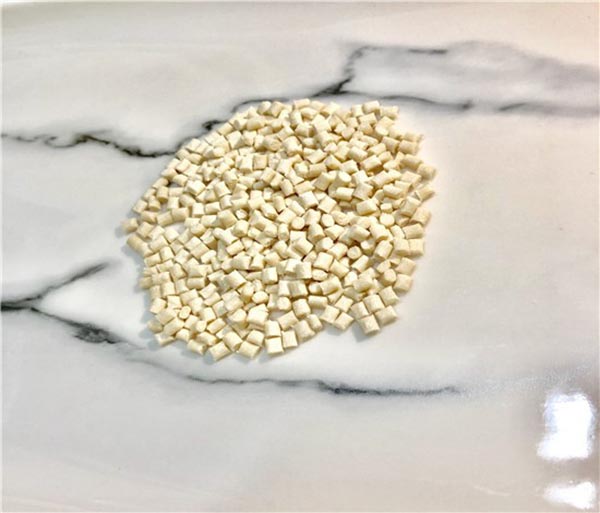

PPO

PPO Performance

Polyphenylether yog poly2, 6-dimethyl-1, 4-phenylether, tseem hu ua polyphenyloxy, Polyphenyleneoxiole (PPO), hloov polyphenylether yog hloov los ntawm polystyrene lossis lwm yam polymers (MPPO).

PPO yog ib hom engineering yas uas muaj kev ua tau zoo heev, hardness siab dua PA, POM, PC, siab txhua yam muaj zog, zoo rigidity, zoo tshav kub kuj (thermal deformation kub ntawm 126 ℃), siab seem stability (shrinkage tus nqi ntawm 0.6%) , qhov nqus dej tsawg (tsawg dua 0.1%).Qhov tsis zoo yog tias UV tsis ruaj khov, tus nqi siab thiab tus nqi me me.PPO yog non-toxic, pob tshab, kuj me me ntom ntom, nrog zoo heev mechanical zog, kev nyuaj siab so, creep kuj, tshav kub tsis kam, dej tsis kam, dej vapor kuj.

Nyob rau hauv ntau yam ntawm qhov kub thiab txias, qhov sib txawv ntawm qhov kev ua tau zoo ntawm cov hluav taws xob zoo, tsis muaj hydrolysis, kev tsim cov shrinkage yog me me, flammable nrog tus kheej-flameout, tsis kam mus rau inorganic acid, alkali, aromatic hydrocarbon kuj, halogenated hydrocarbon, roj thiab lwm yam kev ua haujlwm tsis zoo, yooj yim o los yog kev ntxhov siab tawg, lub ntsiab drawback yog tsis zoo melting liquidity, ua thiab tsim kev nyuaj, feem ntau ntawm cov tswv yim thov rau MPPO (PPO blend los yog alloy).

Txheej txheem yam ntxwv ntawm PPO

PPO muaj cov viscosity siab, tsis muaj kuab lom thiab ua haujlwm siab.Ua ntej ua tiav, nws yuav tsum tau qhuav rau 1-2 teev ntawm qhov kub ntawm 100-120 ℃, qhov kub thiab txias yog 270-320 ℃, pwm tswj qhov kub thiab txias yog qhov tsim nyog ntawm 75-95 ℃, thiab tsim kev ua haujlwm raws li "siab. kub, kub siab thiab kub ceev ".Nyob rau hauv cov txheej txheem ntawm cov yas npias no, dav hlau ntws qauv (nqa qauv) yog ib qho yooj yim uas yuav tsum tau ua nyob rau hauv pem hauv ntej ntawm lub nozzle, thiab lub nozzle ntws channel yog zoo dua.

Qhov tsawg kawg nkaus thickness yog li ntawm 0.060 mus rau 0.125 nti rau cov qauv molded qhov chaw thiab 0.125 mus rau 0.250 nti rau cov qauv ua npuas ncauj qhov chaw.Cov nplaim hluav taws kub ntawm UL94 HB txog VO.

Hom kev thov ntau yam

PPO thiab MPPO feem ntau yog siv rau hauv cov khoom siv hluav taws xob, tsheb, khoom siv hauv tsev, khoom siv hauv chaw ua haujlwm thiab cov tshuab ua haujlwm, thiab lwm yam, siv MPPO thaum tshav kub kub tsis kam, cuam tshuam tsis kam, qhov ntev stability, puas kuj, flaking kuj;

PC

Kev ua haujlwm ntawm PC

PC yog hom tsis muaj ntxhiab, tsis muaj ntxhiab, tsis muaj tshuaj lom, tsis muaj xim tsis muaj xim lossis xim daj me ntsis thermoplastic engineering plastics, nrog rau lub cev zoo thiab cov khoom siv kho tshuab, tshwj xeeb tshaj yog kev cuam tshuam zoo heev, siab tensile zog, khoov lub zog, compression zog;Zoo toughness, zoo tshav kub thiab huab cua tsis kam, yooj yim xim, tsis tshua muaj dej nqus.

Lub thermal deformation kub ntawm PC yog 135-143 ℃, qhov nkag yog me me thiab qhov loj yog ruaj khov.Nws muaj cov cua kub zoo thiab tsis kub tsis kam, cov khoom siv kho tshuab ruaj khov, qhov ruaj khov, cov khoom siv hluav taws xob thiab cov nplaim hluav taws kub nyhiab hauv qhov kub thiab txias.Nws tuaj yeem siv tau ntev ntawm -60 ~ 120 ℃.

ruaj khov rau lub teeb, tab sis tsis tiv taus UV teeb, huab cua tsis zoo;Roj kuj, acid kuj, alkali tsis kam, oxidation acid thiab amine, ketone, soluble nyob rau hauv chlorinated hydrocarbons thiab aromatic kuab tshuaj, inhibit cov kab mob cov yam ntxwv, nplaim retardant yam ntxwv thiab muaj kuab paug kuj, ntev nyob rau hauv dej yooj yim rau hydrolysis thiab tawg, qhov tsis zoo yog vim tsis muaj zog qaug zog, yooj yim los tsim kev ntxhov siab tawg, tsis zoo hnyav tsis kam, fluidity tsis zoo, hnav tsis zoo.PC txhaj tshuaj molding, extrusion, molding, tshuab moulding, luam ntawv, bonding, txheej thiab machining, txoj kev tseem ceeb tshaj plaws yog txhaj molding.

Txheej txheem yam ntxwv ntawm PC

PC cov khoom yog rhiab heev rau qhov kub thiab txias, nws melting viscosity nrog qhov nce ntawm qhov kub thiab txias, txo qis, ceev ceev, tsis rhiab rau lub siab, thiaj li yuav txhim kho nws cov liquidity, coj txoj kev ntawm cua sov.PC cov khoom ua ntej ua tiav kom qhuav (120 ℃, 3 ~ 4 teev), noo noo yuav tsum tswj tsis pub dhau 0.02%, cov dej ua haujlwm ntawm qhov kub siab yuav ua rau cov khoom tsim cov xim turbidious, nyiaj thiab npuas, PC ntawm chav tsev kub muaj peev xwm loj heev. yuam kom siab elastic deformation.Muaj kev cuam tshuam toughness, yog li nws tuaj yeem ua rau txias txias, kos duab txias, txias yob nias thiab lwm yam txheej txheem txias txias.PC cov khoom yuav tsum tau molded nyob rau hauv tej yam kev mob ntawm cov khoom kub, siab pwm kub thiab siab kub thiab tsis muaj ceev.Rau me me sprue, tsawg ceev txhaj tshuaj yuav tsum tau siv.Rau lwm hom sprue, kev kub ceev txhaj tshuaj yuav tsum tau siv.

Pwm tswj qhov kub thiab txias hauv 80-110 ℃ yog qhov zoo dua, ua kom sov hauv 280-320 ℃ yog qhov tsim nyog.

Hom kev thov ntau yam

PC qhov peb daim ntawv thov yog cov iav sib dhos kev lag luam, kev lag luam tsheb thiab khoom siv hluav taws xob, kev lag luam hluav taws xob, ua raws li kev lag luam machinery qhov chaw, optical disc, pej xeem khaub ncaws, khoos phis tawj thiab lwm yam khoom siv hauv chaw ua haujlwm, kev kho mob thiab kev noj qab haus huv, zaj duab xis, kev lom zem thiab khoom siv tiv thaiv.

PBT

Kev ua haujlwm ntawm PBT

PBT yog ib qho nyuaj tshaj plaws engineering cov ntaub ntawv thermoplastic, nws yog cov khoom siv semi-crystalline, muaj tshuaj lom neeg ruaj khov zoo heev, txhua yam muaj zog, hluav taws xob rwb thaiv tsev yam ntxwv thiab thermal stability.Cov ntaub ntawv no muaj kev ruaj ntseg zoo nyob rau hauv ntau yam ntawm ib puag ncig, thiab PBT noo noo nqus cov yam ntxwv tsis muaj zog heev.

Melting point (225% ℃) thiab kub deformation kub yog qis dua cov khoom siv PET.Veka softening kub yog li 170 ℃.Cov iav hloov pauv kub yog nruab nrab ntawm 22 ℃ thiab 43 ℃.

Vim lub siab crystallization tus nqi ntawm PBT, nws viscosity tsawg heev, thiab lub sij hawm voj voog ntawm cov khoom yas ua feem ntau yog tsawg.

Txheej txheem yam ntxwv ntawm PBT

Qhuav: Cov khoom no hydrolyzes yooj yim ntawm qhov kub thiab txias, yog li nws yog ib qho tseem ceeb kom qhuav nws ua ntej ua.Kev pom zoo kom qhuav hauv huab cua yog 120C, 6-8 teev, lossis 150 ℃, 2-4 teev.Cov av noo yuav tsum tsawg dua 0.03%.Yog tias siv lub tshuab ziab khaub ncaws hygroscopic, qhov pom zoo kom qhuav yog 150 ° C rau 2.5 teev.Kev ua haujlwm kub yog 225 ~ 275 ℃, thiab pom zoo kub yog 250 ℃.Rau cov khoom tsis zoo pwm kub yog 40 ~ 60 ℃.

Lub qhov cua txias ntawm cov pwm yuav tsum tau tsim kom zoo kom txo tau qhov kev khoov ntawm cov khoom yas.Thaum tshav kub kub yuav tsum poob sai thiab sib npaug.Nws raug pom zoo tias txoj kab uas hla ntawm pwm txias kab noj hniav yog 12 hli.Kev txhaj tshuaj siab yog nruab nrab (txog 1500bar siab tshaj plaws), thiab tus nqi txhaj tshuaj yuav tsum ceev li sai tau (vim tias PBT solidifies sai).

Khiav thiab rooj vag: Lub voj voog khiav tau pom zoo kom nce siab hloov mus.

Hom kev thov ntau yam

Cov khoom siv hauv tsev (cov khoom siv ua zaub mov, cov khoom siv lub tshuab nqus tsev, cov kiv cua hluav taws xob, lub tshuab ziab plaub hau, cov khoom siv kas fes, thiab lwm yam), cov khoom siv hluav taws xob (switches, hluav taws xob vaj tse, fuse thawv, lub computer keyboards, thiab lwm yam), automotive kev lag luam (radiator grate, lub cev panels, log npog, qhov rooj thiab qhov rais Cheebtsam, thiab lwm yam.

Post lub sij hawm: 18-11-22