Cov txheej txheem ntawm kev hloov pauv cov khoom yas feem ntau suav nrog: txheej txheem sib xyaw, txheej txheem extrusion, ntim.

1. Rau qhov kev xeem ntawm kev sib xyaw: kev them nqi, txais, tu, sib faib, viav vias, sib tov.

2. Lub tshuab ntxuav: nws muab faib ua plaub qib A, B, C thiab D, uas An yog qhov siab tshaj plaws (ntu du), thiab lwm yam.

3. Kev sib faib khoom: xyuas kom meej tias cov khoom siv raw yuav tsis yuam kev hauv kev ua haujlwm.

4. Kev sib xyaw: qhov kev txiav txim ntawm kev sib tov yog: particle hmoov, toner.

Ⅱ.Pub.

Los ntawm kev tswj lub computer, blanking yog tswj raws li qhov hnyav hloov.

Qhov zoo:

1. Txheeb xyuas qhov tseeb ntawm cov khoom sib faib.

2. Txo qhov delamination ntawm cov ntaub ntawv.

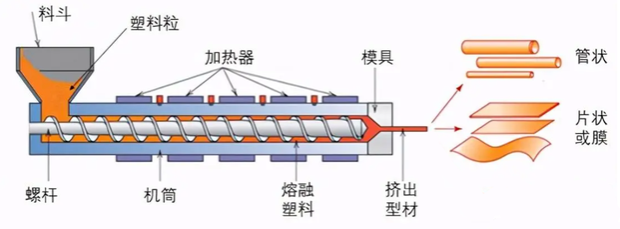

Ⅲ.Ntsia hlau plasticizing, extrusion, kos duab.

Ⅲ.Ntsia hlau plasticizing, extrusion, kos duab.

Ⅳ.Dej txias (lub dab dej).

Txias thiab txias cov yas strip extruded los ntawm extruder.

Ⅴ.Cua ziab (dej twj tso kua mis, cua riam).

Tshem tawm cov dej noo los ntawm cov hlua yas thiab qhuav nws.

Ⅵ.Granulation.

Feem ntau, qhov luaj li cas ntawm cov khoom txiav yog 3mm * 3mm PVC khoom txheem: GB / T8815-2002.

Ⅶ.Sifting (vibrating npo).

Lim cov khoom txiav thiab tswj qhov loj ntawm cov khoom.

Ⅷ.Overmagnetization (magnetic filter).

Tshem tawm cov khoom nrog hlau impurities.

Ⅸ.Kev tshuaj xyuas ntawm qhov chaw.

Nws yog qhov tseem ceeb ntawm kev tswj xyuas, uas kuaj pom seb cov xim ntawm cov khoom puas yog raws li tus qauv thiab seb nws puas koom ua ke.

Ⅹ.Mixing (ob lub khob hliav qab sib tov).

Xyuas kom meej tias cov xim thiab kev ua haujlwm ntawm cov khoom siv yas hloov tau zoo ib yam.

Ⅺ.Ntim (tag nrho-electronic quantitative ntim tshuab).

Ⅻ.Cia

Post lub sij hawm: 23-12-22