(1) Qhov cuam tshuam ntawm cov khoom siv raw

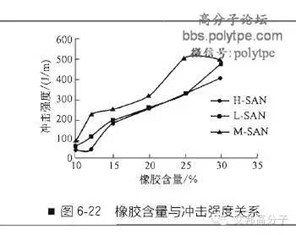

Cov hom sib txawv ntawm PC thiab ABS resin sib xyaw ntawm cov hlau muaj qhov sib txawv hauv kev ua tau zoo.Nws tuaj yeem pom los ntawm daim duab 6-22 tias cov ntsiab lus roj hmab siab txhim kho qhov cuam tshuam lub zog ntawm PC / ABS system, tab sis ua rau muaj kev puas tsuaj rau kev sib nrig sib capacitance tus cwj pwm ntawm cov theem, yog li txo cov tensile zog ntawm cov alloy.Yog li ntawd, xaiv ABS nrog cov ntsiab lus roj hmab uas tsim nyog tuaj yeem tsis tsuas yog txhim kho qhov cuam tshuam lub zog ntawm kev sib xyaw, tab sis kuj txhim kho nws lub zog khoov sib koom ua ke.Thaum siv ABS nrog cov ntsiab lus roj hmab tsawg, lub zog khoov ntawm cov hlau yuav tshwm sim ua kom muaj zog.Tsis tas li ntawd, siab acrylonitrile, roj hmab cov ntsiab lus thiab siab molecular hnyav ABS tuaj yeem txhim kho cov cua sov ntawm cov hlau.

(2) Kev cuam tshuam ntawm PC / ABS sib piv ntawm cov khoom ntawm cov hlau

Lub compatibility thiab txhua yam khoom ntawm PC / ABS blend system yog ncaj qha ntsig txog cov ntsiab lus ntawm txhua yam hauv lub cev.Cao Mingan et al.tau txais ntau yam PC / ABS alloys nrog cov yam ntxwv sib txawv los ntawm kev kho qhov sib xyaw ntawm PC thiab ABS resin.Cov khoom ntawm PC / ABS alloy muaj kev sib raug zoo nrog cov ntsiab lus ntawm ABS, thiab kwv yees li ua raws li cov khoom siv ntxiv.Tag nrho cov khoom ntawm PC / ABS alloy yog nruab nrab ntawm PC thiab ABS, thiab qhov cuam tshuam lub zog muaj cov nyhuv superadditivity (piv txwv li cov nyhuv synergy) thiab cov nyhuv antagonism nrog qhov kev faib ua feem.

(3) Qhov cuam tshuam ntawm peb feem

Lub tshav kub tsis kam thiab thermal stability ntawm PC / ABS alloy tuaj yeem txhim kho los ntawm kev ntxiv benzothiazole thiab polyimide.Lub fluidity ntawm PC / ABS alloy tuaj yeem txhim kho los ntawm kev ntxiv cov kev hloov pauv xws li ethylene oxide / propylene oxide block copolymer, MMA / St copolymer thiab olefin / acrylic vinegar copolymer.Tsis tas li ntawd, txhawm rau txhim kho kev sib koom ua ke ntawm PC / ABS alloy txhaj tshuaj, PMMA, SAN, SBR, acrylic vinegar elastomer, tsis tshua muaj polyolefin, ethylene / acrylic vinegar / acetic acid, ethylene (vinegar) copolymer, PC / ethylene thaiv los yog graft copolymer thiab lwm yam tshuaj feem ntau yog ntxiv.

(4) Qhov cuam tshuam ntawm kev siv tshuab

PC thiab ABS kev sib xyaw cov cuab yeej tuaj yeem xaiv los ntawm cov ntsia hlau ntxaib extruder thiab ib qho ntsia hlau extruder nrog cov khoom zoo li qub.Jong Han Chun ntseeg hais tias cov nyhuv ntawm kev nruam kneading extruder yog qhov zoo tagnrho.Nyob rau hauv cov nqe lus ntawm blending hom, cov nyhuv ntawm kev txiav txim thib ob yog zoo dua.Txawm li cas los xij, nyob rau hauv qhov kev txiav txim thib ob blending, ib feem ntawm cov ntaub ntawv yuav tsum tau extruded ob zaug ntawm qhov kub thiab txias, uas muaj zog noj, yooj yim rau degrade cov ntaub ntawv thiab txo cov khoom ntawm cov alloy.

Cov txheej txheem molding kuj muaj kev cuam tshuam zoo rau cov morphology thiab cov qauv ntawm PC / ABS alloy.Piv txwv li, cov qauv tsim los ntawm kev nias yas tuaj yeem tswj tau zoo dua microstructure heterogeneous dispersion xeev tsim los ntawm kev sib xyaw alloy, thaum txhaj tshuaj molding, ntawm qhov siab shear npaum li cas, lub xeev dispersion hloov thiab mus txog ntau yam tsis zoo decomposition.Yog li ntawd, qhov cuam tshuam lub zog ntawm ob qhov qauv muaj qhov sib txawv zoo, thiab qhov cuam tshuam lub zog ntawm cov qauv compression molding yog siab.PC hauv dej (cov ntsiab lus dej ntau dua 0.03%) thiab kub siab (kub siab dua 150 ℃) hauv qhov yooj yim degradation, yog li hauv kev sib xyaw lossis molding ua ntej ziab, yuav tsum tsis txhob muaj stearic acid lubricants tov, thiaj li tsis cuam tshuam rau kev ua tau zoo ntawm cov khoom.

Post lub sij hawm: 02-06-22