Txhaj Tshuaj Qib Hloov PPS- GF, Fr rau Auto Teeb Pom Kev

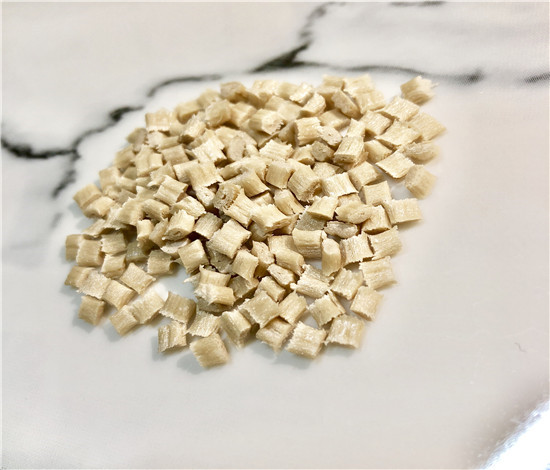

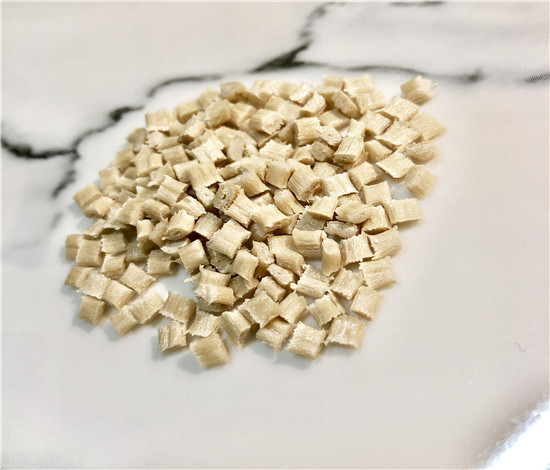

Polyphenylene sulfide yog cov yas tshuab yas, feem ntau siv niaj hnub no raws li kev ua tau zoo thermoplastic. PPS tuaj yeem ua pwm, extruded, lossis machined kom nruj. Hauv nws daim ntawv ntshiab, nws yuav yog opaque dawb rau lub teeb ziab hauv cov xim. Qhov kev pabcuam kub tshaj plaws yog 218 ° C (424 ° F). PPS tsis tau pom kom yaj nyob rau hauv ib qho kuab tshuaj nyob hauv qab kwv yees li xyoo 200 ° C (392 ° F).

Polyphenylene sulfide (pps) yog ib qho organic polymer muaj cov txiv ntoo uas muaj ntxhiab uas tau sib txuas los ntawm cov leej faj. Khoom cua Fiber thiab Textiles tau muab los ntawm cov polymer no tiv tshuaj tshuaj thiab cua sov tawm tsam. PPS yog siv nyob rau hauv lim ntaub rau Coal boilers, papermaking paptors, zaj duab xis, cov tshuaj tsw heev, gaskets, thiab cov roj. PPS yog cov ua ntej ua ntej rau kev ua haujlwm polymer ntawm ib nrab-pas dej polymer. Tus pps, uas yog lwm yam insulating, tuaj yeem hloov pauv mus rau daim ntawv semiconducting los ntawm oxidation lossis siv dopants.

PPS yog ib qho tseem ceeb tshaj plaws kub thermoplastic polymers vim tias nws ua yeeb yam ib tug xov tooj ntawm cov khoom xav tau. Cov khoom no suav nrog kev tiv thaiv tshav kub, acids, alkalis, mildew, cov tshuaj txhuam hniav, kev laus, thiab kev puas tsuaj. Nws nqus tau cov tshuaj me me ntawm cov kuab tshuaj thiab tiv qhov zas.

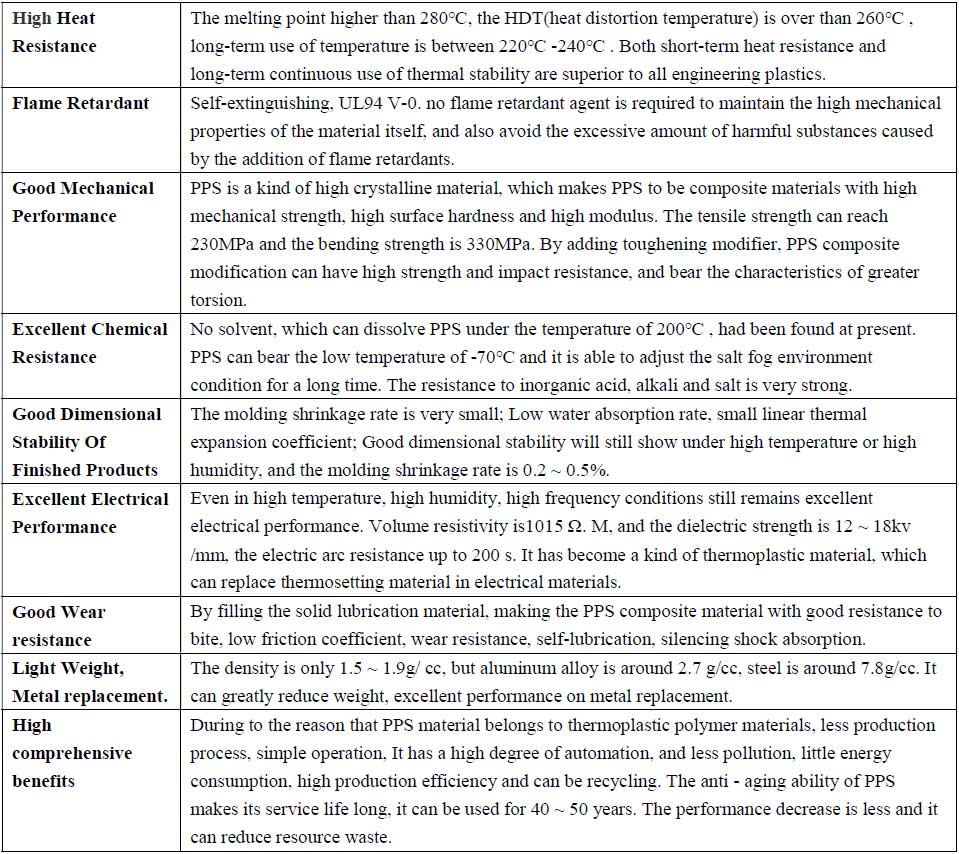

PPS nta

Cov tshav kub kub tau tsis kam, txuas ntxiv siv ntsuas kub txog li 220-240 ° C, iav Fiber ntxiv txhawb cov cua sov kub tshaj 260 ° C

Cov nplaim hluavtaws zoo retardant thiab tuaj yeem hloov kho ul94-v0 thiab 5-va (tsis muaj dripping) yam tsis muaj ntxiv ib qho nplaim liab ntxiv.

Cov tshuaj ua tau zoo heev, tsuas yog thib ob rau PTFE, yuav luag Insoluble hauv txhua cov organic kuab tshuaj

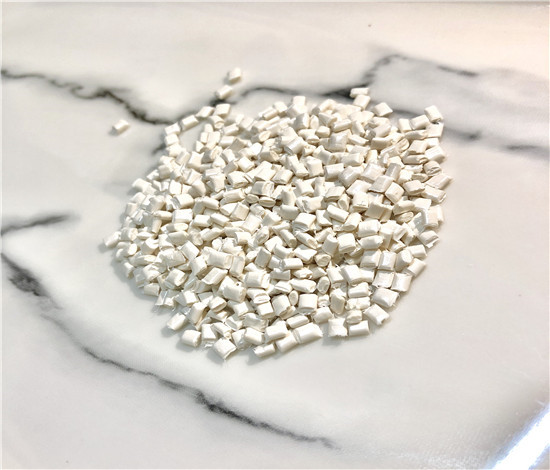

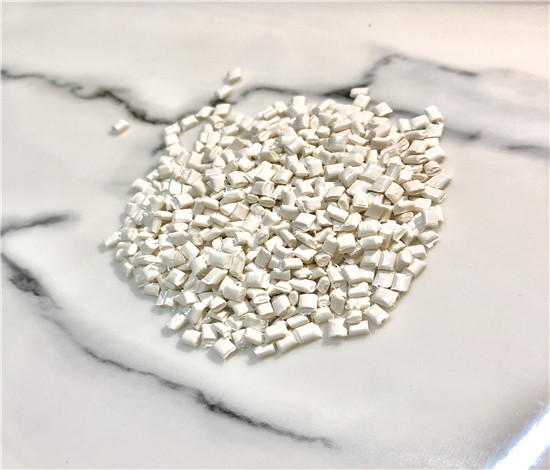

PPS resin yog txhawb nqa los ntawm cov iav fiber ntau lossis cov roj carbon fiber thiab muaj cov khoom siv tshuab zog muaj zog, nruj thiab nkag tsis tau. Nws tuaj yeem hloov ib feem ntawm cov hlau li cov khoom siv.

Lub resin muaj cov khoom ruaj khov zoo heev.

Txaj me me moulding shrinkage tus nqi, thiab cov dej tsis haum. Nws tuaj yeem siv nyob rau hauv cov kub siab lossis siab siab huab cua.

Zoo fluidity. Nws tuaj yeem txhaj tshuaj molding rau hauv cov nyom thiab nyias-walled seem.

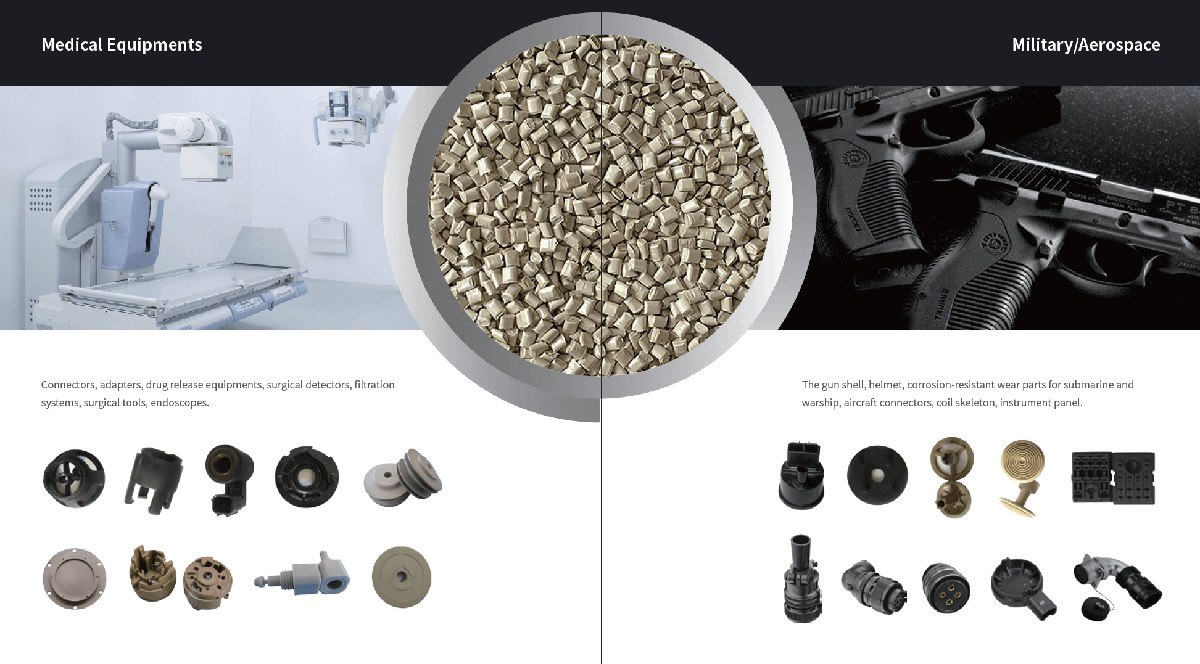

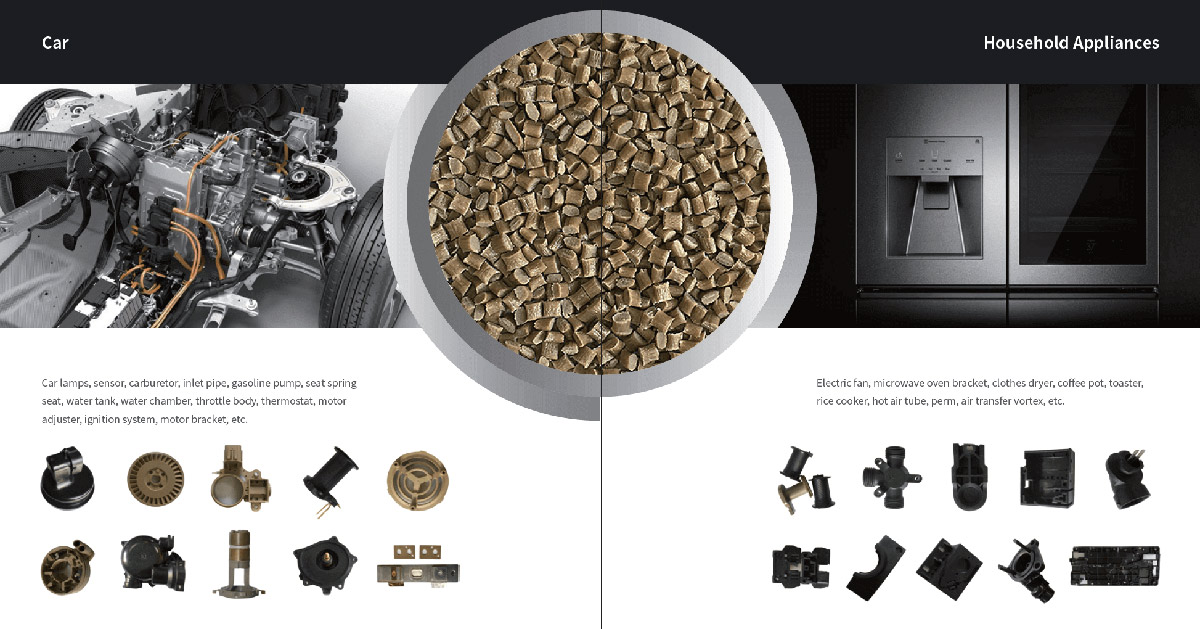

PPS Lub ntsiab ntawv thov teb

Dav siv nyob rau hauv cov tshuab, ntsuas, cov khoom siv hluav taws xob, cov khoom lag luam hluav taws xob, cov khoom lag luam hauv tsev, cov khoom lag luam roj, cov khoom lag luam roj thiab qee cov khoom lag luam engineering.

| Tshav pob | Cov Khoom Siv Thov |

| Automotive | Hla Txuas, Nres Piston, Nres Sensor, teeb BRACKET, ETC |

| Khoom Siv Hauv Tsev | Cov plaub hau thiab nws cov rwb thaiv tsev cua sov, hluav taws xob rab phom pob taub hau, nqaij grinder cutter taub hau, cd player lub taub hau txheej txheem |

| Lub tshuab | Tso kua dej, roj twj tso kua mis khoom siv, cuam tshuam, kabmob, iav, thiab lwm yam |

| Khoom siv hluav taws xob | Connectors, Accessories, Reps tuaj, tshuab luam ntawv, daim npav Slots, thiab lwm yam |

Cov Ntawv Qeb Khoom Sib Xws

Dav siv nyob rau hauv cov tshuab, ntsuas, cov khoom siv hluav taws xob, cov khoom lag luam hluav taws xob, cov khoom lag luam hauv tsev, cov khoom lag luam roj, cov khoom lag luam roj thiab qee cov khoom lag luam engineering.

| Khoom | Kev qhia tshwj xeeb | Siko Qib | Sib npaug rau cov hom hom & Qib |

| Lub pps | PPS + 40% GF | Sps90g40 | Phillips R-4, Polycuplastics 1140A6, Toray A504X90, |

| PPS + 70% GF thiab cov pob zeb rau | Sps90gm70 | Phillips R-7, Polyplastics 6165A6, Toray A410Mx07 |