Biodegradable Txhaj Molding Hloov Khoom

Ob peb txoj kev lag luam muaj peev xwm siv tau (piv txwv li qhov hnyav molecular) PLA.Ob lub ntsiab monomers yog siv: lactic acid, thiab cyclic di-ester, lactide.Txoj kev uas feem ntau mus rau PLA yog lub nplhaib-qhib polymerization ntawm lactide nrog ntau yam hlau catalysts (feem ntau tin octoate) hauv kev daws los yog kev ncua.Cov tshuaj tiv thaiv hlau-catalyzed nyhav ua rau racemization ntawm PLA, txo nws cov stereoregularity piv rau cov khoom pib (feem ntau yog pob kws hmoov txhuv nplej siab).

PLA yog soluble nyob rau hauv ntau yam ntawm cov organic solvents.Ethyl acetate, vim nws qhov yooj yim ntawm kev nkag mus thiab tsis tshua muaj kev pheej hmoo ntawm kev siv, yog qhov txaus siab tshaj plaws.PLA 3D tshuab luam ntawv filament dissolves thaum soaked nyob rau hauv ethyl acetate, ua rau nws yog ib qho tseem ceeb hnyav rau ntxuav 3D luam ntawv extruder hau los yog tshem tawm PLA kev txhawb nqa.Cov ntsiab lus kub ntawm ethyl acetate yog tsawg txaus los kuj smooth PLA nyob rau hauv lub vapor chamber, zoo li siv acetone vapor rau du ABS.

Lwm cov kuab tshuaj nyab xeeb siv suav nrog propylene carbonate, uas muaj kev nyab xeeb dua li ethyl acetate tab sis nyuaj rau kev yuav khoom lag luam.Pyridine kuj tseem siv tau tab sis qhov no tsis muaj kev nyab xeeb dua li ethyl acetate thiab propylene carbonate.Nws kuj muaj qhov txawv ntawm cov ntses tsis zoo.

SPLA Txhaj Moulding Nta

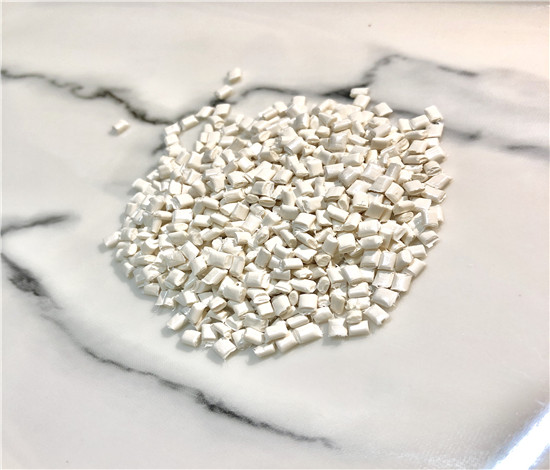

Cov khoom tseem ceeb ntawm cov khoom yog PLA, PBAT thiab inorganic Cov khoom no muaj cov meltfluidity zoo thiab muaj zog txhua yam, thiab tshwj xeeb tshaj yog tsim rau kev txhaj tshuaj molding.Nws tuaj yeem tsim cov khoom lag luam ntau cov kab noj hniav nrog lub sijhawm txias txias, tus nqi qis, thiab degradation ceev.Cov khoom muaj kev ua haujlwm zoo thiab lub cev muaj zog, thiab tuaj yeem siv ncaj qha rau kev txhaj tshuaj molding los ua cov khoom sib txawv.

SPLA Txhaj Molding Daim Ntawv Thov Field

High toughness, siab zog 3D luam ntawv hloov khoom siv,

Tus nqi qis, siab zog 3D luam ntawv hloov cov ntaub ntawv

SPLA Txhaj Moulding Qib Thiab Nqe Lus Qhia

| Qib | Kev piav qhia | Cov lus qhia ua |

| SPLA-IM115 | Cov khoom tseem ceeb ntawm cov khoom yog PLA, PBAT thiab inorganic Cov khoom no muaj cov meltfluidity zoo thiab muaj zog txhua yam, thiab tshwj xeeb tshaj yog tsim rau kev txhaj tshuaj molding. | Thaum siv cov khoom no rau kev txhaj tshuaj molding, nws raug pom zoo tias qhov kev txhaj tshuaj kub yog 180-195 |