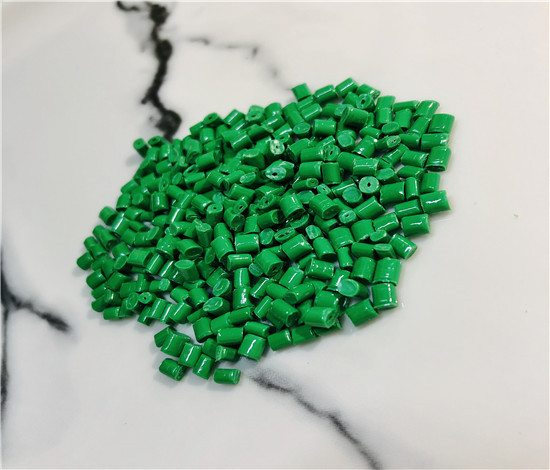

PI (polyimide) hmoov, pas nrig, ntawv, cnc tsim cov khoom lag luam

Thermosetting polyamides yog paub rau thermal stability, cov tshuaj zoo, thiab cov yam ntxwv zoo nkauj / daj xim. Polyamities compounded nrog graphite lossis khob fiber ntau reights muaj qhov ua tau zoo ntawm 340 mpa (49,000 moduli ntawm 21,000 mpa (3,000,000 PSI). Thermoses polymer matrix polyamides pom kev ua tau zoo heev thiab lub zog qis tensile lub zog. Cov khoom no yog tswj xyuas thaum siv sijhawm ntev mus txog 232 ° C (450 ° F) thiab rau kev mus ncig ua si, kom siab li 704 ° F). [11] Moulded polyimimide seem thiab laminates muaj cov kub ua kom zoo heev. Kev ua haujlwm ib txwm txias rau cov ntu thiab laminates ntau yam los ntawm cryogenic rau cov tshaj li 260 ° C (500 ° F). Polyamides kuj tseem muaj kev tiv thaiv kom cov nplaim hluavteeb rau cov nplaim taws thiab tsis tas yuav tsum tau sib xyaw nrog nplaim taws retardants. Feem ntau nqa cov ul ul ntsuas ntawm VTM-0. Polyimaus laminates muaj lub zog flexural zog ib nrab ntawm 249 ° C (480 ° F) ntawm 400 teev.

Raug polyimide seem tsis cuam tshuam los ntawm cov kuab tshuaj uas nquag siv thiab roj, suav nrog cov roj hydrocarbons, esters, dej cawv thiab ferns. Lawv kuj tawm tsam cov kua qaub tsis muaj zog tab sis tsis pom zoo rau kev siv nyob rau hauv ib puag ncig uas muaj cov alkalis lossis inorganic acids. Qee cov polyamides, xws li CP1 thiab Corin XLS, yog cov kuab tshuaj-solu-soluble thiab nthuav tawm cov teeb pom kev kub siab. Cov khoom siv solubility qiv rau lawv rau ntawm cov tshuaj tsuag thiab tsis tshua muaj tshuaj kho cov ntawv thov.

PI NTA

PI yog nws tus nplaim taws retardant polymer, uas tsis hlawv ntawm kub kub

Cov khoom siv neeg kho tshuab qis rhiab heev rau qhov kub

Cov khoom siv muaj lub peev xwm zoo nkauj, tuaj yeem ua tiav cov kev xav tau ntawm cov xim sib kis

Zoo heev thermal kev ua tau zoo: kub thiab kub tsis kam

Kev Ua Yeeb Yam Hluav Taws Xob: Kev Rwb Thaiv Tsev Hluav Taws Xob Siab Hluav Taws Xob

PI lub ntsiab ntawv thov teb

Dav siv nyob rau hauv cov tshuab, ntsuas, cov khoom siv hluav taws xob, cov khoom lag luam hluav taws xob, cov khoom lag luam hauv tsev, cov khoom lag luam roj, cov khoom lag luam roj thiab qee cov khoom lag luam engineering.

Cov khoom siv polyimide yog lub teeb ci, hloov tau, tiv taus cua sov, tiv thaiv kom sov thiab tshuaj lom neeg. Yog li ntawd, lawv tau siv rau hauv cov khoom siv hluav taws xob rau cov cable yoog thiab ua ib qho kev ua yeeb yaj kiab ntawm cov hlau nplaum. Piv txwv li, hauv lub laptop computers, cov cable uas txuas cov pawg loj logic rau cov zaub (uas yuav tsum tau qhib lossis kaw) yog feem ntau lub hauv paus polyimide nrog tooj liab. Piv txwv ntawm cov yeeb yaj kiab polyimide suav nrog kev ua lej aperical, istilex, vtec pi, norton th thiab kaptrex.

Kev siv ntxiv ntawm Resin Polyimide yog raws li cov txheej txheem insulating thiab passivation txheej hauv kev tsim cov khoom sib xyaw ua ke thiab cov mems. Txheej polyimide muaj cov tshuab elongation zoo elongation thiab tensile lub zog, uas kuj tseem yuav pab cov nplaum polyimide thiab cov txheej txheej hlau.

| Tshav pob | Cov Khoom Siv Thov |

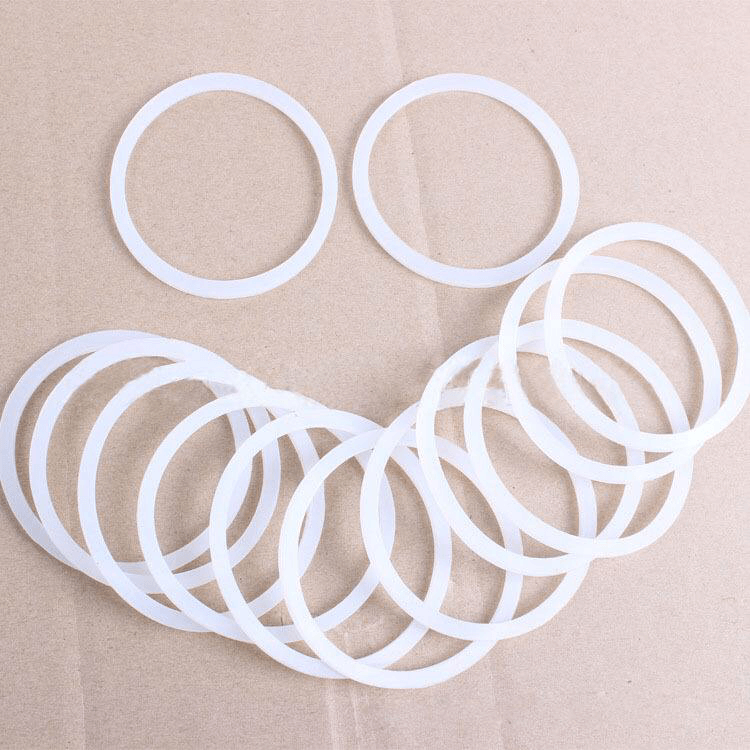

| Kev Lag Luam Tshooj | Qhov kub siab rau tus kheej lubricating cov kabmob, compressor piston nplhaib, Foob Raj nplhaib |

| Hluav Taws Xob Cov Khoom Siv Hluav Taws Xob | Radiators, kiv cua txias, qhov rooj kov, roj tank cap, cua nkag grille, dej tank npog, teeb nrog |

SPRA-3D qib thiab lus piav qhia

| Teem nqi | Kev piav txog |

| Spla-3D101 | Kev ua haujlwm siab PLA. Pla account rau ntau dua 90%. Cov luam ntawv tau zoo thiab siv tau. Qhov zoo yog qhov ua tiav ruaj khov, du tshuab luam ntawv thiab cov khoom siv tau zoo heev. |

| Spla-3DC102 | Cov account Pla rau 50-70% thiab feem ntau tau sau thiab ua kom nruj. Qhov zoo ua rau tsim kev ua yeeb yam, du luam ntawv Andexcellent cov khoom siv mechanenent. |