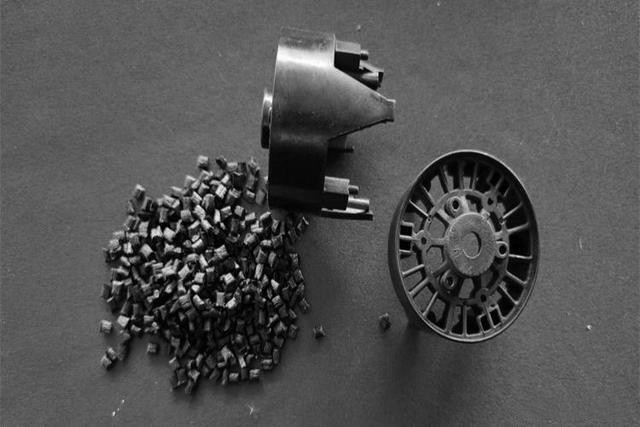

Qee tus neeg xav tias hloov cov hlau nrog PPS yas yuav txo cov khoom lag luam zoo. Qhov tseeb, kev siv PPS hloov cov hlau tuaj yeem txhim kho cov khoom lag luam zoo hauv ntau lub sijhawm.

Cov khoom siv PPS muaj qhov zoo ntawm cov kev kub siab kuj, muaj zog, tshuaj lom neeg ua haujlwm, nkag mus sab nrauv, kev ruaj khov ruaj khov thiab lwm yam. Nws tuaj yeem hloov cov hlau tsis muaj peev xwm hloov chaw, tooj liab, txhuas, alloys thiab lwm cov hlau, thiab suav tias yog qhov hloov tau zoo tshaj plaws rau cov hlau. Nyob rau hauv xyoo tsis ntev los no, qhov tau ntawm daim ntawv thov ntawm polyphenylene sulfide tau nthuav dav, kev thauj khoom, thiab hloov cov hlau nrog yas tau dhau los ua kev thoob ntiaj teb Cov.

Vim Li Cas PPSzoo tshaj ntawm kev hloov cov hlau?

PPS Yas Yog Lub Hnub Qub Rising. Nws tsis tsuas yog khaws cov yam ntxwv zoo ntawm kev ua kom zoo nkauj ntawm cov plastics zoo tib yam, tab sis kuj muaj qhov kub siab thiab tshuab siv zog dua li kev ua kom zoo tib yam.

1. Kev ua haujlwm siab

Hloov kho lub pps Cov yas yog ib qho zoo tshaj plaws ntawm engineering plastics nrog kev kub kub ua kom zoo, thiab nws cov thermal deformation kub feem ntau yog tshaj 260 ° C. Tsis tas li ntawd, nws tseem muaj qhov zoo ntawm cov pob zeb me me, muaj zog ua haujlwm, nws tseem muaj hluav taws xob kub siab, nws tseem muaj hluav taws xob zoo, yog li nws Yuav siv tau rau hauv ntau cov ntawv thov hloov cov hlau ua cov ntaub ntawv engineering.

2. Cov Khoom Qub Zog

Qhov tshwj xeeb nqus ntawm lub pps yas yog txog 1.34 ~ 2.0, uas tsuas yog 1/9 ~ 1/2 ntawm 1/2 ntawm txhuas. Cov cuab yeej ntawm PPS no yog qhov tseem ceeb rau cov khoom siv neeg kho tshuab xws li tsheb, thiab dav hlau uas yuav tsum tau txo qis hauv qhov hnyav.

3. Lub Zog Siab

Rau tib lub ntim ntawm cov khoom, lub zog ntawm PPS feem ntau yog qis dua li ntawm cov hlau, tab sis vim tias sib zog dua li hlau, PPS muaj zog dua li cov hlau dog dig. Ntawm cov txheej txheem uas twb muaj lawm, nws muaj kev siv siab tshaj plaws.

4. Yooj yim raukev ua

Cov khoom samps PPS feem ntau yog tsim nyob rau ib zaug, thaum cov khoom lag luam hlau feem ntau yuav tsum tau mus dhau ob peb, kaum ob, lossis txawm tias kaum los ua kom tiav. Qhov tshwj xeeb ntawm PPS yog qhov tseem ceeb heev los khaws lub sijhawm ua haujlwm thiab nce ntxiv kev tsim khoom. Lub machining ntawm plastics yog yooj yim. Cov khoom yas yog siv dav hauv kev lag luam tsheb, uas feem ntau yog cov kev npaj ua qauv thiab cov ntaub ntawv uas tsis yog yuav tsuas yog txhim kho cov nqi ntawm kev ua, sib dhos thiab txij nkawm. Nws kuj tseem tuaj yeem txo cov hluav taws xob tau siv lub tsheb.

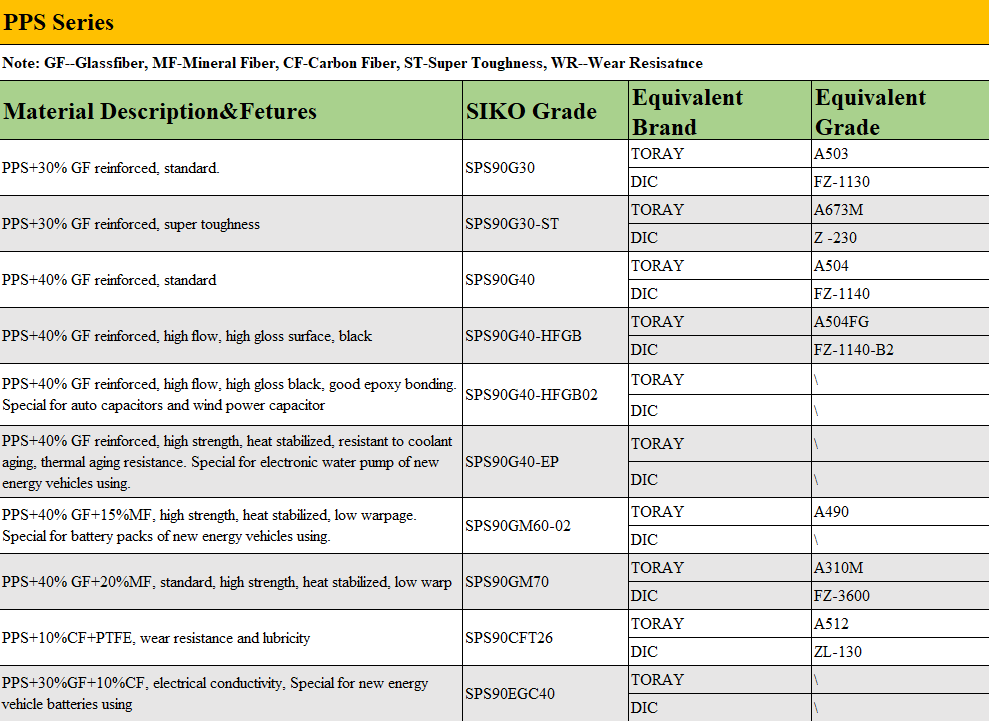

Sikopolers 'qib tseem ceeb ntawm PPS thiab lawv cov hom sib txig sib luag thiab qib, raws li hauv qab no:

Raws li tuaj yeem pom los ntawm cov lus saum toj no, Sikopolymers 'pps muaj:

Zoo dua qhov ruaj khov stability: qis deformation ntawm qhov chaw nyob hauv qab kev mob kub thiab txias

Txo cov dej nqus dej tsawg: qhov qis dua cov khoom laus laus lub sijhawm siab dua thiab muaj cov kev txhawb nqa muaj zog thiab kev tiv thaiv

Siab kub tiv thaiv: Kev ua si zoo dua cua sov.

Tsis tas li ntawd, PPS muaj cov txheej txheem zoo dua, txo cov nqi zog thiab cov nqi qis dua.

Lub Sijhawm Post: 29-07-22