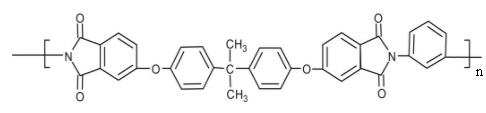

Polyetherimide, hu ua PEI hauv Lus Askiv, Polyetherimide, nrog lub ntsej muag zoo nkauj, yog ib yam ntawm amorphous thermoplastic tshwj xeeb engineering yas uas qhia txog kev hloov pauv ether daim ntawv cog lus (- Rmae Omi R -) rau hauv cov khoom siv polyimide ntev saw molecules.

Structure of PEB

Raws li ib hom thermoplastic polyimide, PEI tuaj yeem txhim kho qhov tsis zoo ntawm cov thermoplasticity thiab kev ua haujlwm nyuaj ntawm polyimide los ntawm kev qhia txog ether daim ntawv cog lus (- Rmurrurr R -) rau hauv cov saw hlau polymer thaum tuav lub nplhaib qauv ntawm polyimide.

Cov yam ntxwv ntawm PEI

Qhov zoo:

Lub zog tensile siab, siab tshaj 110MPa.

Siab dabtsi yog khoov zog, siab tshaj 150MPa.

Zoo heev thermo-mechanical bearing muaj peev xwm, thermal deformation kub ntau dua los yog sib npaug rau 200 ℃.

Zoo creep kuj thiab qaug zog kuj.

Cov nplaim hluav taws zoo heev thiab cov pa taws tsawg.

Zoo heev dielectric thiab rwb thaiv tsev zog.

Zoo zoo dimensional stability, tsawg coefficient ntawm thermal expansion.

Kev kub siab ua haujlwm, tuaj yeem siv tau ntawm 170 ℃ rau lub sijhawm ntev.

Nws tuaj yeem dhau los ntawm microwaves.

Qhov tsis zoo:

Muaj BPA (bisphenol A), uas txwv nws daim ntawv thov hauv cov khoom me nyuam mos.

Notch cuam tshuam rhiab heev.

Alkali tsis kam yog dav dav, tshwj xeeb tshaj yog nyob rau hauv cov cua kub.

PEB

PEEK lub npe tshawb fawb polyether ether ketone yog ib hom polymer uas muaj ib daim ntawv cog lus ketone thiab ob daim ntawv cog lus ether hauv cov qauv saw tseem ceeb.Nws yog cov khoom siv polymer tshwj xeeb.PEEK muaj lub ntsej muag beige, kev ua haujlwm zoo, zawv zawg thiab hnav tsis kam, kev nkag siab zoo, tshuaj lom neeg ua haujlwm zoo, ua haujlwm zoo rau hydrolysis thiab superheated chav, kub hluav taws xob, kub thermal deformation kub thiab zoo sab hauv hluav taws kub retardancy.

PEEK yog thawj zaug siv nyob rau hauv lub tshav dav hlau aerospace los hloov txhuas, titanium thiab lwm yam ntaub ntawv hlau los ua rau sab hauv thiab sab nraud ntawm lub dav hlau.Vim tias PEEK muaj cov khoom zoo heev, nws tuaj yeem hloov cov khoom siv xws li hlau thiab ceramics hauv ntau qhov tshwj xeeb.Nws qhov kub thiab txias tsis kam, nws tus kheej lubrication, hnav tsis kam thiab qaug zog ua haujlwm ua rau nws yog ib qho ntawm cov khoom siv hluav taws xob nrov tshaj plaws.

Raws li cov khoom siv thermoplastic polymer, cov yam ntxwv ntawm PEI zoo ib yam li cov PEEK, lossis txawm tias hloov PEEK.Cia wb mus saib qhov txawv ntawm ob.

| PEI | PEB | |

| Qhov ceev (g / cm3) | 1.28 | 1.31 ib |

| Tensile zog (MPa) | 127 | 116 |

| Flexural zog (Mpa) | 164 | 175 |

| Pob Indentation Hardness (MPa) | 225 | 253 |

| GTT (Lub iav-hloov kub) (℃) | 216 | 150 |

| HDT (℃) | 220 | 340 |

| Ua haujlwm ntev (℃) | 170 | 260 |

| Surface Specific Resistance (Ω) | 10 14 | 10 15 |

| UL94 nplaim retardant | V0 | V0 |

| Kev nqus dej (%) | 0.1 | 0.03 ib |

Piv nrog PEEK, qhov kev ua tau zoo ntawm PEI yog qhov muag pom ntau dua, thiab nws qhov txiaj ntsig loj tshaj plaws nyob rau hauv tus nqi, uas tseem yog qhov laj thawj tseem ceeb vim li cas qee cov khoom siv dav hlau tsim tau xaiv los ntawm PEI cov ntaub ntawv sib xyaw.Tus nqi ntawm nws cov khoom yog qis dua cov hlau, thermosetting composites thiab PEEK composites.Nws yuav tsum tau muab sau tseg tias txawm hais tias tus nqi kev ua tau zoo ntawm PEI kuj siab, nws qhov kub thiab txias kuj tsis siab dhau.

Hauv cov kuab tshuaj chlorinated, kev ntxhov siab tawg tshwm sim tau yooj yim, thiab kev tiv thaiv rau cov kuab tshuaj organic tsis zoo li ntawm semi-crystalline polymer PEEK.Hauv kev ua, txawm tias PEI muaj cov txheej txheem ntawm cov khoom siv thermoplastic engineering yas, nws xav tau kev kub siab dua.

Post lub sij hawm: 03-03-23