Pwm kub yog hais txog qhov kub ntawm cov pwm kab kab noj kab kab uas tuaj rau hauv kev sib cuag nrog cov khoom lag luam hauv kev txhaj tshuaj molding cov txheej txheem. Vim hais tias nws cuam tshuam ncaj qha rau cov khoom txias ntawm cov khoom lag luam hauv cov pwm kab noj hniav, uas muaj qhov cuam tshuam zoo rau kev ua tau zoo sab hauv thiab yam ntxwv zoo ntawm cov khoom.

1. Cov nyhuv ntawm pwm kub ntawm cov tsos ntawm cov khoom.

Siab dua tuaj yeem txhim kho fluinity ntawm lub cob, uas feem ntau ua rau cov khoom du thiab ci, tshwj xeeb yog txhim kho cov iav fiber ntau ntxiv txhawb nqa cov khoom lag luam. Nyob rau tib lub sijhawm, nws kuj tseem txhim kho lub zog thiab cov tsos ntawm kab fusion.

Raws li rau cov etched nto, yog tias cov pwm kub yog tsawg, uas ua rau cov khoom lag luam saum npoo av, uas ua rau cov khoom lag luam saum npoo av, thiab "hloov pauv" tsis tuaj yeem ncav cuag cov pwm tiag tiag Cov. Qhov zoo tshaj plaws etching nyhuv tuaj yeem tau los ntawm kev nce cov pwm ua kom txias thiab txias.

2. Cuam tshuam rau sab hauv kev ntxhov siab ntawm cov khoom.

Qhov tsim ntawm kev tsim sab hauv kev ntxhov siab yog tshwm sim los ntawm qhov sib txawv thermal shrinkage thaum txias. Thaum cov khoom tsim tawm, nws txias zuj zus txuas ntxiv los ntawm saum npoo rau sab hauv, thiab cov thawj ua ntej shrinks thiab hardens, thiab tom qab ntawd maj mam mus rau sab hauv. Hauv cov txheej txheem no, sab hauv kev ntxhov siab yog tsim vim qhov sib txawv hauv shrinkage ceev.

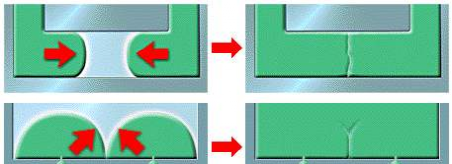

Thaum lub sijhawm muaj kev ntxhov siab sab hauv hauv cov yas yog siab dua ntawm cov kev txwv ywj, lossis hauv qab kev yaig ntawm qee qhov kev sib tw, cov kab nrib pleb yuav tshwm sim nyob rau ntawm cov khoom yas. Txoj kev tshawb fawb ntawm PC thiab PMA pob dawb pob tshab qhia tau hais tias lub sijhawm nyob sab hauv kev ntxhov siab hauv cov txheej sab hauv yog compressed thiab inner txheej yog txuas ntxiv.

Lub chaw sib xyaw ua ke rau ntawm nws cov khoom txias txias, thiab cov pwm txias ua rau cov khoom siv hluav taws xob txias sai sai, uas ua rau cov khoom siv hluav taws xob sai sai, uas ua rau cov khoom siv hluav taws xob sai sai, uas ua rau cov khoom siv hluav taws xob sai, uas ua rau cov khoom siv hluav taws xob nrawm nrawm.

Cov pwm kub yog qhov tseem ceeb tshaj plaws los tswj hwm sab hauv kev ntxhov siab. Yog tias lub pwm ntsuas kub tau hloov me ntsis, qhov kev ntxhov siab sab hauv kev ntxhov siab yuav tau hloov heev. Feem ntau hais lus, kev pom zoo sab hauv kev ntxhov siab ntawm txhua cov khoom lag luam thiab cov khoom lag luam muaj nws qhov ntsuas kub qis tshaj plaws. Thaum tsim nyias-walled lossis ntev ntws nrug, cov pwm kub yuav tsum tau siab dua qhov tsawg kawg nkaus ntawm kev molding dav dav.

3. Txhim kho cov khoom lag luam.

Yog tias tus tsim ntawm cov kab cua txias ntawm cov pwm uas tsis tsim nyog los yog cov pwm kub tsis tswj tau kom zoo, thiab cov khoom yas tsis txias txaus, nws yuav ua rau cov yas ntim rau warp.

Rau qhov ntsuas kub ntawm cov pwm, qhov sib txawv ntawm qhov sib txawv ntawm cov pwm thiab pwm tsis zoo, lub pwm hluav taws xob tsis zoo, lub tshuab pwm tsis zoo, yog txiav txim siab raws li cov khoom lag luam, yog li kom tswj tau Lub txias txias shrinkage tus nqi ntawm txhua feem ntawm cov moulding. Tom qab doiloulding, cov yas seem yuav khoov mus rau qhov kev coj ua nrog kub siab dua, yog li ua kom cov kab ke tawm ntawm cov kab sib txawv ntawm cov kab ke sib sau ua ke. For the plastic parts with completely symmetrical shape and structure, the mold temperature should be kept consistent accordingly, so that the cooling of each part of the plastic part should be balanced.

4. Ua rau cov tshuaj moulding ntawm cov khoom.

Qhov qis dua pwm kub ua kom muaj cov molecular "khov kho ntawm lub zog ntawm cov roj khov, yog li txo cov tshuaj moulding ntawm cov khoom. Ntawm qhov tsis sib xws, thaum cov pwm kub muaj siab, cov neeg caij sov yog qhov qis, thiab nws tau txais txiaj ntsig kom ntev, thiab nws muaj txiaj ntsig zoo rau cov khoom lag luam loj dua.

5. Cuam tshuam cov kub deformation kub ntawm cov khoom.

Especially for crystalline plastics, if the product is molded at a lower mold temperature, the molecular orientation and crystallization are instantly frozen, and the molecular chain will be partially rearranged and crystallized in a higher temperature environment or secondary processing conditions, which makes the product deform Ntawm lossis txawm tias qis dua li cov thermal deformation kub (hdT) ntawm cov khoom siv.

Txoj kev tseeb yog siv cov kev pom zoo pwm kub kom ze rau ntawm nws cov khoom lag luam thiab tsis txhob muaj cov khoom siv hluav taws xob thiab rov qab-shrinkage nyob rau hauv ib puag ncig cua sov.

Hauv ib lo lus, pwm kub yog ib qho ntawm cov kev tswj hwm kev txhaj tshuaj ntau tshaj plaws hauv kev txhaj tshuaj molding, thiab nws tseem yog thawj qhov kev txiav txim siab hauv pwm tsim.

Nws cov cawv ntawm kev sib sau, cov txheej txheem theem nrab thiab kev siv cov khoom siv zaum zaum kawg tsis tuaj yeem raug mob siab.

Lub Sijhawm Post: 23-12-22