Cov khoom siv polymer ntxig yog cov khoom siv polymer nrog ntau cov hws tsim los ntawm cov roj dispersed hauv cov khoom siv polymer.

Lub cuab yeej tshwj xeeb tshaj plaws yog qhov zoo heev rau kev thov cov suab-nqus cov ntaub ntawv, sib cais thiab adsorption, yeeb tshuaj sustained tso tawm, pob txha scaffold thiab lwm daim teb.

Cov khoom siv tsoos ib txwm muaj, xws li polypropylene thiab polyurethane, tsis yooj yim ua degraded thiab noj roj av raws li cov khoom muaj kuab paug, uas yuav ua rau ib puag ncig muaj kuab paug.

Yog li ntawd, cov tib neeg pib kawm biodegradable qhib-lub qhov khoom.

Daim ntawv thov ntawm Pla Qhib-Qhov Khoom Siv:

Pla qhib-qhov khoom siv kuj muaj qee qhov tsis zoo, uas txwv nws daim ntawv thov hauv thaj chaw qhib cov khoom, xws li:

1. Crisp kev ntxhib los mos, lub zog tensile qis thiab tsis muaj qhov tsis muaj tseeb ntawm cov khoom siv perforated.

2

Yog tias sab laug hauv lub cev ntev li ib qho tshuaj, nws tuaj yeem ua rau o.

3. Ntws.

Tsis tshua muaj affinity rau cov hlwb, yog tias ua rau hauv cov pob txha cuav lossis scaffold cell yog qhov nyuaj rau kev ua raws li kev ua raws li thiab Proliferate.

Txhawm rau txhim kho qhov tsis txaus ntseeg ntawm PLA qhib cov khoom, sau, copolymerization thiab lwm txoj hauv kev tau coj los txhim kho cov ntaub ntawv qhib-lub dab.

Cov hauv qab no yog ob peb txoj kev hloov kho ntawm PLA:

1.pla / pcl blending hloov kho

Pcl, lossis polycaprolactone, tseem yog cov khoom siv biodegradable nrog zoo biocompatibility, kev muaj zog thiab tensile lub zog.

Nrog rau cov PLA tuaj yeem txhim kho kom zoo tensile lub zog ntawm PLA.

Cov kws tshawb nrhiav pom tias cov khoom tuaj yeem tswj tau los ntawm kev tswj hwm tus piv ntawm PCL rau PLA. Thaum cov pawg sib piv ntawm cov pla rau PCL yog 7: 3, lub zog tensile thiab modulus ntawm cov khoom tau siab dua.

Txawm li cas los xij, txoj kev nruj me me txo qis nrog kev nce ntawm cov kab uas hla.

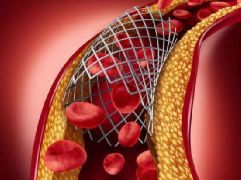

Cov khoom siv PLA / PCL yog qhov tsis muaj tshuaj lom thiab muaj cov ntawv thov me me ntawm cov nqaij kub vascular.

2.pla / pbat muab kev muab hloov kho

PBAT yog cov khoom siv degradable, uas muaj cov tsis muaj kev cuam tshuam ntawm cov aliphatic polyester thiab cov tawv ntawm cov muaj ntxhiab tsw polyester. Tus Brittleness ntawm PLA tuaj yeem txhim kho tom qab sib xyaw nrog PLA.

Cov kev tshawb fawb qhia tau hais tias nrog kev nce ntawm PBAT cov ntsiab lus, lub porosity yog qhov siab tshaj plaws thaum muaj PBAT cov ntsiab lus yog 20%), thiab qhov tawg tau elongation nce.

Tshaj tawm, txawm hais tias ntxiv ntawm PBAT txo lub tensile lub zog ntawm pla, lub tensile lub zog ntawm pla tseem nce ntxiv thaum nws tau ua rau hauv cov khoom qhib.

3.Pla / PBS Blending Hloov Kho

PBS yog cov khoom siv biodegradable, uas muaj cov tshuab ua kom zoo, yooj yim heev kub kuj, hloov kho tau zoo thiab muaj peev xwm sib luag rau pp thiab cov ntaub ntawv tsis tuaj yeem.

Blend PBS nrog PLA tuaj yeem txhim kho tus brittleness thiab cov txheej txheem ntawm PLA.

Raws li kev tshawb fawb, thaum cov pawg sib piv ntawm PLA: PBS tau 8: 2, cov nyhuv zoo yog qhov zoo tshaj plaws; Yog hais tias PBS tau ntxiv rau hauv ntau dhau, qhov porosity ntawm qhib cov khoom siv yuav raug txo kom tsawg.

4.Pla / Bioactive iav (BG) Filling kev hloov kho

Raws li cov khoom siv iav zoo nkauj, BG feem ntau yog tsim ntawm silicon calcium phosphorus oxide, uas tuaj yeem txhim kho cov khoom siv tshuab hluav taws xob thiab cov khoom lag luam ntawm PLA.

Nrog rau kev nce ntawm BG cov ntsiab lus, lub tensile modulus ntawm cov khoom siv qhib-lub zog ntau ntxiv, tab sis lub zog tensile thiab elongation thaum tawg.

Thaum BG cov ntsiab lus yog 10%, lub porosity ntawm qhib-lub qhov khoom yog qhov siab tshaj plaws (87.3%).

Thaum cov ntsiab lus BG ncav cuag 20%, lub zog compressive ntawm cov composite yog qhov siab tshaj plaws.

Ntxiv mus, cov ntaub ntawv sib xyaw / BG Composite Porous tuaj yeem tso nyiaj ostUeoid apatite txheej ntawm lub cev thiab sab hauv cov kua dej hauv lub cev, uas tuaj yeem ua pob txha ua pob txha lov. Yog li ntawd, PLA / BG muaj lub peev xwm siv tau rau hauv pob txha pob txha ntaus.

Lub Sijhawm Post: 14-01-22