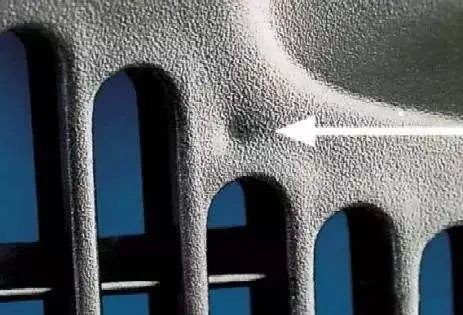

Nyob rau hauv cov txheej txheem ntawm cov khoom lag luam ntau lawm, khoom lag luam dents thiab pores yog qhov muaj kev phom sij ntau tshaj plaws. Cov yas txhaj rau cov pwm shrinks hauv ntim hauv ntim raws li nws txias. Lub saum npoo hadens ua ntej thaum nws txias ua ntej, thiab daim ntawv npuas hauv sab hauv.

Qhov indentation yog lub qeeb txias ib feem ntawm npuas nyob rau hauv cov kev taw qhia ntawm kev cog lus ntawm concave nto; Qhov thiaj li hu ua staa yog hais txog cov khoom hauv pwm ua los ntawm cov khoom siv los ntawm saum npoo, uas yog qhov tsis txaus rau tag nrho cov pwm ntawm cov pwm. Vim tias vim li no, qhov nyob rau hauv lub xeev lub xeev yog tsim, uas feem ntau tshwm sim nyob rau hauv cov tuab ntawm cov khoom thiab txhaws chaw nres nkoj.

Cov ntaub ntawv nrog cov dej siab siab kuj tseem ceeb rau indentation. Thaum hloov pauv kev sib npaug los tshem tawm qhov indentation, lub chaw teeb tsa yuav tsum tau teeb tsa hauv kev taw qhia ntawm shrinkage. Ntawd yog, pwm kub thiab chim ntsuas txo qis, txhaj tshuaj tiv thaiv siab, tab sis nws yuav tsum tau sau tseg tias qhov no yuav ua rau muaj kev ntxhov siab sab hauv kev ntxhov siab.

Vim hais tias qhov indentation yog inconspicuous, yog li nws tsis cuam tshuam rau cov tsos ntawm cov txheej txheem hauv cov pwm ua corrosion, xws li striated, granular thiab li ntawd.

Txo kev tuag tuag txias kom txo tiav yog tseem ua tau yog tias cov khoom siv roj molding yog cuam tshuam polystyrene hips (ib hom polystyrene ps). Tab sis ib zaug ib qho kev kho hniav tshwm sim hauv cov hau kev no, nws yog qhov nyuaj los kho cov khoom polished.

Cov khoom lag luam pob tshab nrog cov pa cua yog qhov teeb meem, cov khoom siv opaque nrog cov pa roj tsis muaj cov nyom siv thiab yuav tsum tsis txhob pom hauv cov khoom.

Vim tias cov dej thiab cov zaub mov ua los ntawm stomata, feem ntau diffented rau txhua feem ntawm cov khoom, cov duab ntawm lub stomata feem ntau me me.

Ua ntej, kev daws

Tam sim no: Ua kom lub zog txhaj tshuaj, txo lub cav kub thiab kub thiab kub thiab kub thiab kub thiab txias thiab kub thiab txias thiab txias thiab txias thiab txias thiab txias thiab txias, nyob rau hauv qhov chaw ntawm indentation yuam kev txias.

Lub sij hawm luv luv: Sau lub ntug sab saud uas indentation yog ua. Qhov twg cov hniav yog tsim, cov khoom siv yog tuab raws li nws hla qhov chaw nqaim.

Lub Sij Hawm Ntev: Cov tuab tuab ntawm cov qauv cov khoom yuav tsum tau zam tag. Ib qho yooj yim rau cov khoom siv hniav ua kom yooj yim, ntev thiab cov duab nqaim yuav tsum yog luv li sai tau. Yuav tsum nce lub rooj vag, channel tseem ceeb, shunt, nozzle lub. Txhim kho pa.

Thib ob, siv teeb meem

1 Moulding shrinkage ntawm cov khoom loj indentation kuj tseem loj, xws li polypreylene PP, txawm tias ntev npaum li cas yog me ntsis kev pab, yuav ua rau indentation.

| Khoom | Mould Shrinkage Tus Nqi |

| PS | 0.002 ~ 0.006 |

| PP | 0.01 ~ 0.02 |

| PE | 0.02 ~ 0.05 |

2. Thaum qhov kub yog txo kom tsis muaj dents, yog tias cov khoom siv hauv cov pwm kab noj hniav yog tseem tsis tau pom tias tsis muaj nqi zog yuav ua. Lub siab ntawm cov khoom nyob ib puag ncig pwm nyob hauv pwm, uas yog, lub siab zoo li qub, tsis yog txhua qhov chaw.

Ze rau lub rooj vag ib feem ntawm lub siab yog qhov siab, yog tias hloov ntawm lub rooj vag thiab ze ntawm lub qhov siab sib txawv nrog tag nrho siab piv rau qhov sib txawv me me yuav tsis Tsim dents, kuj tseem tsis tau muaj cov khoom lag luam cuam tshuam rau sab hauv.

Thaum qee cov khoom siv ntws mus rau hauv qhov chaw nyuaj, muaj lub siab nyob rau hauv qhov chaw no, thiab lub siab txo nyob rau lwm qhov chaw, ua rau dents. Qhov no feem ntawm qhov kev kub siab ntawm qhov kev ntxhov siab ntawm cov khoom lag luam kuj loj. Nyob rau hauv cov mob zoo, cov khoom siv fluidity yog qhov zoo dua thaum ntsuas kub ntawm cov khoom nce nrog qhov kub ntawm kev tuag, thiab kev txhaj tshuaj hauv lub siab zoo li qub lub xeev tseem yuav qis dua.

3. Hauv kev hloov pauv ntawm cov xwm txheej, kev sib xyaw ua ke ntawm qhov kub thiab lub siab thiab lub sijhawm yuav tsum tau ua ua ntej ntawm lub rooj, txhawm rau paub cov txiaj ntsig. Ua ntej tshaj plaws, thaum lub sijhawm ua tau ntev heev, nws yog qhov yooj yim kom paub txhua qhov kev hloov me me hauv siab. Nws yuav tsum raug sau tseg tias cov txiaj ntsig tau los thaum qhov ntsuas kub hloov yuav tsum tau tsim tom qab kev txhaj tshuaj thiab tom qab qhov ntsuas kub.

4. Txhawm rau txiav txim siab rau cov laj thawj tshwm sim los ntawm cov khoom siv ntawm cov tshuab yas, yog tias cov khoom siv hluav taws xob, feem ntau yog cov teeb meem khoom, yog tias nws yog tom qab txias , Nws yog tus pwm lossis txhaj tshuaj tiv thaiv.

Lub Sijhawm Post: 03-11-22