Txhaj Yeeb-GF, FR Rau Cov Khoom Siv Hluav Taws Xob

Daim ntawv thov POM rau kev txhaj tshuaj-Mould-molds engineering cov khoom siv, cov pob txha caj dab, rab phom sib tsoo, riam phom, thiab xauv. Cov khoom siv tau dav siv nyob rau hauv automotive thiab consumer electronics kev lag luam.

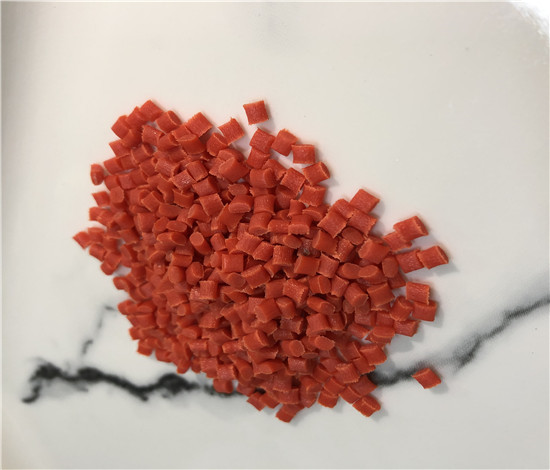

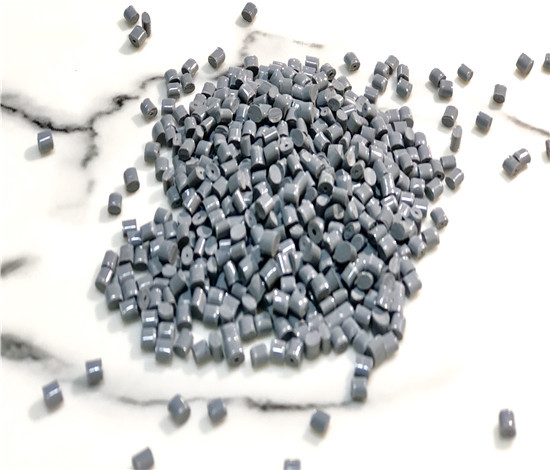

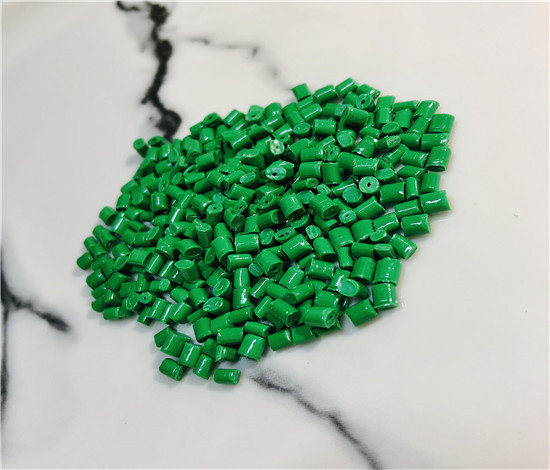

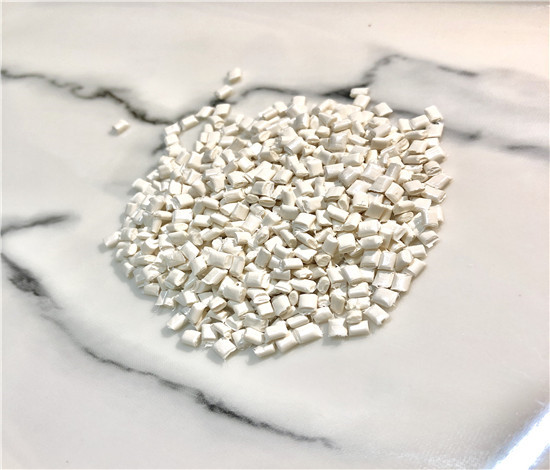

Pom yog tus cwj pwm los ntawm nws lub zog siab, hardness thiab rigidity rau -40 ° C. Pom yog intrinsically opaque dawb vim tias nws cov khoom siv siab crystalline tab sis tuaj yeem tsim tawm hauv ntau cov xim. [3] Pom muaj qhov ntom ntom ntawm 1.410-1.420 g / cm3.

Pom yam ntxwv

Pom yog txoj kev du, ci, tawv, ntom ntom, daj ntseg daj lossis dawb, nrog nyias nyias uas yog translucent.

Pom muaj lub zog siab, txhav txhav, elasticity zoo thiab zoo hnav tsis kam. Nws cov khoom siv zoo heev, lub zog tshwj xeeb txog li 50.5MPA, muaj zog tshwj xeeb txog li 2650mpa, ze rau cov hlau.

Pom tsis tiv thaiv muaj zog acid thiab oxidant, thiab muaj qee yam ruaj khov kom enoic acid thiab cov kua qaub tsis muaj zog.

Pom muaj cov tshuaj tiv thaiv zoo, thiab tuaj yeem tiv taus hydrocarbons, roj, aldehydes, thiab tuaj yeem tswj hwm cov tshuaj muaj peev xwm ntawm cov ntsuas kub.

Pom muaj huab cua tsis zoo.

Pom lub ntsiab lus app daim ntawv thov

Dav siv nyob rau hauv cov tshuab, ntsuas, cov khoom siv hluav taws xob, cov khoom lag luam hluav taws xob, cov khoom lag luam hauv tsev, cov khoom lag luam roj, cov khoom lag luam roj thiab qee cov khoom lag luam engineering.

| Tshav pob | Cov Khoom Siv Thov |

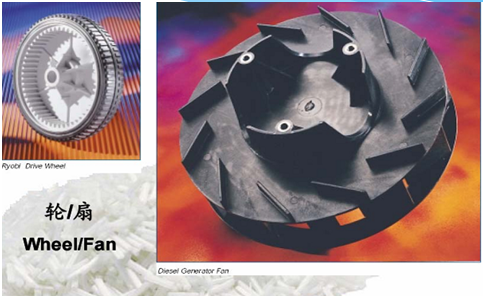

| Cov Chaw Pib | Radiators, kiv cua txias, qhov rooj kov, roj tank cap, cua nkag grille, dej tank npog, teeb nrog |

| Khoom siv hluav taws xob | Hloov tus tuav, tab sis kuj tuaj yeem ua xov tooj, kaw lus xov tooj, vis dis aus, TV thiab khoos phis tawj, cov chaw sau ntawv, kab xev |

| Cov Khoom Siv Neeg Kho Tshuab | Siv rau kev tsim khoom ntau lub zog, chais, bearings, conveyor siv tawv |

Siko POM Cov Qib thiab Cov Lus Qhia

| Siko Qib Tsis muaj. | Sau (%) | Fr (UL-94) | Kev piav txog |

| SPM30G10 / G20 / G25 / G30 | 10%, 20%, 25%, 30% | HB | 10%, 20%, 25%, 30% gfreinforced, hig rigidity. |