Kev Lag Luam Tsheb

Kev siv cov nylon pa66 hauv cov tsheb yog qhov tshaj plaws, feem ntau yog nyob ntawm cov kws kho mob nylon zoo heev. Txoj kev hloov kho ntau yam tuaj yeem ua tau raws li cov kev xav tau ntawm ntau yam ntawm lub tsheb.

Lub Pa66 cov khoom yuav tsum muaj cov cai hauv qab no:

Raug Daim Ntawv Piav Qhia

Daim Ntawv Thov:Nws Pib Qhov Hluav Taws Xob-Radiators & Intercooler

Khoom siv:Pa66 nrog 30% -33% gf txhawb nqa

Siko Qib:SP90g30HSL

Cov txiaj ntsig:Lub zog siab, lub siab tawv, cua sov ua hauj, kev ua haujlwm kub, cov tshuaj lom neeg ua haujlwm, ruaj khov ruaj khov.

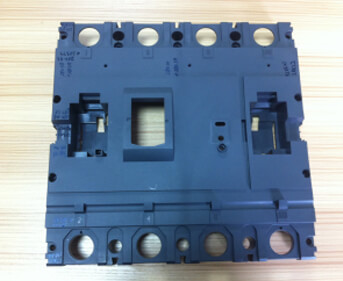

Daim Ntawv Thov:Hluav Taws Xob Qhov Hluav Taws Xob-Hluav Taws Xob Meters, Tej Fais Fab, Thiab Cov Txuas

Khoom siv:PA66 nrog 25% GF txhawb, nplaim taws Retardant Ul94 v-0

Siko Qib:SP90G25F (GN)

Cov txiaj ntsig:

Lub zog siab, cov khoom siv siab, cuam tshuam ntau,

Zoo heev ntws muaj peev xwm, kev moulding yooj yim thiab xim yooj yim,

Nplaim taws retardant ul 94 v-0 halogen-dawb thiab phosphorus-dawb EU Kev Tiv Thaiv Ib puag ncig yuav tsum muaj,

Cov hluav taws xob rwb thaiv tsev hluav taws xob zoo nkauj thiab vuam Kuj;

Daim Ntawv Thov:Qhov Chaw Muaj Khoom

Khoom siv:Pa66 nrog 30% --- 50% gf befleced

Siko Qib:SP90g30 / G40 / g50

Cov txiaj ntsig:

Lub zog siab, siab tawv, siab cuam tshuam, cov khoom siv siab,

Cov peev txheej zoo heev, moulding yooj yim

Tsawg thiab kub ua hauj ntawm -40 ℃ rau 150 ℃

Docensional ruaj, du nto thiab pub dawb ntawm ntab fibers,

Cov huab cua zoo tiv thaiv thiab UV tsis kam